NOTE: this is a bit long but has information to help get more successful inserts.

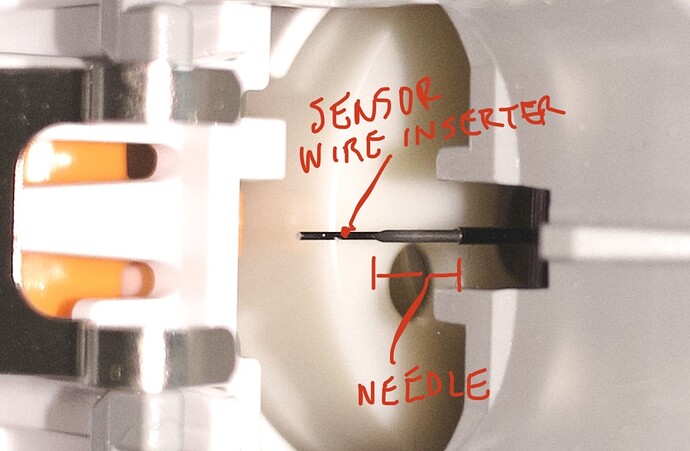

Most commonly the contact flap is the part getting stuck. It gets stuck when the sequence of actions in the mechanism gets disturbed. There is a spring that is supposed to push the flap out of the insert position because the needle has to pass underneath to insert the sensor wire. When the needle retraction gets slowed down, going in or coming out, the spring (finger like silver tabs you see after the insert is completed) cannot push down on the contact flap and stays stuck in the insertion position in the inserter. This is why the whacking technique works best.

When it is stuck, wiggle the inserter gently and move it to and fro to help the whack release the contact flap.

Do not pull it away when whacking it, it will get stuck even more.

Some may wonder how I was able to see this happen. I dismantled, reassembled, observed and tested the mechanism many many times to find out why it gets stuck. I was able to reproduce the jam and get it released multiple times.

The key to giving yourself the best chance of keeping the mechanism from getting stuck is to make sure nothing disrupts the path of the needle as it insert the wire and retracts into the inserter. Things like angle, getting the adhesive secure before release, nothing sticky in the path of the needle, firm skin, not a lot of pressure on the skin before release, don’t lift it up until it has completed the insertion, and avoid pushing the needle through anything but skin.

Another issue I’ve seen in user pictures and duplicated is the needle going through the plastic bottom of the sensor. This can happen if the inserter is pushed too hard down in the skin or tilted with the inserter bottom not flat and parallel to the skin surface.

Hope this is helpful.

I’m sure sorry users are having issues, I’ll be cheering when this mechanism is retired and the g7 is here.

Helpful hints…

There are about eight mechanical things that have to happen to get the wire in and release the inserter.

Any interruption in one of those actions in the process will stop the next action.

Make sure the adhesive is stuck, the inserter is flat on the skin, there is no lean of the inserter, the inserter is not putting pressure enough to deform skin, there is no twist or sliding pressure on the inserter.

After pressing the release hold the inserter down for a count of two, listen for the second clic or flop sound before the lift.

Then last, lift it straight up.